Why some companies will never be Lean / Agile?

- Nino Sipina

- Dec 12, 2019

- 10 min read

Lean = highest efficiency, with lowest cost and highest quality.

The word LEAN means that you deliver your product or service as expected by the customer and with the least amount of losses at given time. Lean, like Agile, is originated from Toyota Production System®, or Toyota Just In Time®. It represents a number of methods (Genchi Genbutsu - Genba, Poka-Yoke; Muri, Mura, Muda, Hensei, Kanban, Hoshin Kanri, Hyojunka, Jidoka, Taimuri,…) which ensure continuous real-time improvement (KAIZEN - kai = good; zen = change).

Binding Lean exclusively to business processes is wrong. Therefore, many fails to introduce Lean. Simply because some problems cannot be solved by changing the process. Lean recognizes 7 types of losses (7 wastes). It places the causes of these losses into categories: (1) Management; (2) Bad material and / or suppliers (3) Machines, tools, vehicles, (4) Employee productivity (5) mother nature and (6) process or method errors. Lean can be successfully deployed by those companies that are willing to transform conventional management methods and focus to customer, operational teams and innovation.

At numerous sites you will find Lean principles. They promote the 5 principles. Most of them are focused solely on processes. Processes is just one of the 6 possible causes and by changing the processes only, you will fail to get the expected result. Many companies using Agile/Scrum terms. They have implemented Agile/Scrum processes, they appointed people to the roles, they use special applications, but their projects or services are still late and employee unproductive. The only correct measure of implementing the Lean/Agile methodology is the success of delivering the project, services or product to the customer in time, quantity and quality and at the optimum cost.

With this article, I will try to point out the basic mistakes when introducing Lean. I hope that those who have tried and are not satisfied will find the causes of dissatisfaction, and those who are just about to introduce, not to repeat others' mistakes.

1. Wrong Customer Perception - Voice of Customer

If you were to conduct an anonymous survey of employees and if they would honestly (emotionally) answer the question of who “BUYs” what they do, I believe that over 90% of them would answer - the OWNER of the company. The owner can be personified by a superior boss.

The owner gives goals (KPIs), he asks to make a business plan, he gives a salary and a bonus, he can fire, send to education, reward. The owner directly affects the life and career of each employee. Not a customer.

The employee's income and career are not dependent on the customer at all.

In traditional management models, the VOICE OF THE OWNER is much louder than the VOICE OF THE CUSTOMER.

Lean assumes that there are internal and external customers and that there is a value chain to the end customer. The external customer's expectations are aligned across the value chain so that each department in the chain meets the expectations of its internal customer. In this way, the voice of the customer is transferred from the external through the immediate internal customers up to the last in the chain. Additionally, if you stick result to customer (internal or external) expectation to employee reward you make a first step to Lean.

Until focus of all your employees is not on a real customer (internal or external) you will not be able to introduce Lean!

2. Wrong value system – business/corporate culture

In most company, we like it or not, business value system is defined by KPI metrics. KPI’s often turns organizational units to close gates and doors to each other focusing only on their own targets.

In a managerial workshop I had attended, former adviser to Jack Welch, later a professor at a business school in Switzerland, said that the best companies rarely have a Controlling department and do not set up KPIs like us!? I know several companies (in the world) that give all employees the same KPI. Furthermore, it is enrolled in an Employment Contract and never changes! It looks like this: “Deliver to customer in quantity, quality and time frame”. If this goal is achieved, everyone gets a 13th and / or 14th salary, and if not, no one. I had the extraordinary pleasure working for such the one 20 years ago. Today, that company is one of the largest, most innovative and successful in the industry (see Allseas.com).

The fundamental difference between Lean company and most of today is the way it promotes corporate values and business culture.

If customer feel that the value for money is not adequate and feels “cheated”, they will leave you. If employees feel they are not being valued and respected in an adequate manner, the best will leave you. If your suppliers see that you are not the right partner, they will leave you.

Companies that live and promote the right corporate values and culture daily have no need to advertise them on posters. On their posters are their successes stories - the results of corporate culture. Culture and values come from owners and management, and they are spread out to employees. If managers are only loyal to themselves (careers), they cannot expect employees to be different. In such companies, employees are first and foremost focused on personal earnings, followed by careers, and eventually customers.

Kazuo Inamori (Founder of Kyocera Corporation): “So many people think only about their own profits. But business opportunities rarely knock on their door. "

3. Misunderstanding the Difference Between Value Chain and Process

Individual KPI’s and the absence of a value chain creates SILOS’s. On the other hand, bad business processes will cause administration boom, the constant lack of employees and enormous number of change requests to IT Dept. Silos are most often caused by a management model, and poor processes by micro-management and micro-control.

We know that company organization can be a problem for company efficiencies. In big companies, employees don't know each other, they must send signed and approved paper if they need something from each other. One day, when you say that it's easier to work with external partners than with your own employees, you've come to the point where you need to make a serious change. Most companies think they may handle this with processes and micro-control. On the contrary, it is likely to make things worse. Because you haven’t change Root Cause – untrusty culture and policies.

Process or single task by itself has no Value. It takes a part of cost. The result that a process delivers has the value. This result is a product or service that is delivered by a supplier (internal or external) to a customer (internal or external). All the results together make the final product for an external customer.

Value to the customer is the quantity of products/services delivered in time, quality and cost/price. Process is a component of cost but not the value.

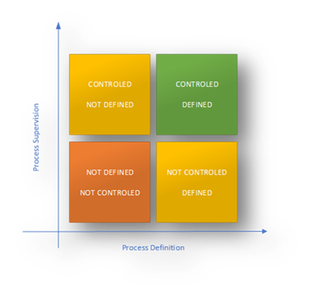

A lot of Lean companies have not designed processes deeply in BPM tools (even in manufacturing industry). But they have a very well defined and supervised value chain (supervision is not the same as control). They measure outcome only.

Other companies focus so much on the design and implementation of the process, the micro-control of each step in the process. At the end day, they forget why they are doing this - "They can't see the forest from the tree." This creates a bunch of administrative tasks where someone clicks, approves, validates, dispatches, redirects, controls, and escalates. After the initial short-term success these clicks and approvals the boss gives the secretaries, the employees cease to be afraid and everything goes back to old - unproductive. And the secretaries, neither guilty nor obliged, got more work. Unfortunately, everyone remembers brief success, but no one explains why it happens. They repeat the same again, reintroduce new controls and management tasks, and once again it's good, then again failed, and even worse finally. Only the secretaries get more work😊 However, few people recognize these cycles and the processes gets increasingly complicated. One day, someone will realize that you are doing stupid things and say stop investment in processes because no productivity improvement. Status quo will remain in the processes. But the secretaries will get a new job: Daily mailing with new directions until secretaries are declared redundant and fired.

Without establishing value chains or Value Stream Mapping (VSM), you will never discover that the cause is management, not the process. VSM will show that in the cost structure of your product, most of the cost is made up by micro-tasks and micro-controls, which further reduce the productivity of both managers and employees. Unfortunately, the business culture is already so disrupted that saving time by streamlining processes will not change the outcome so quickly.

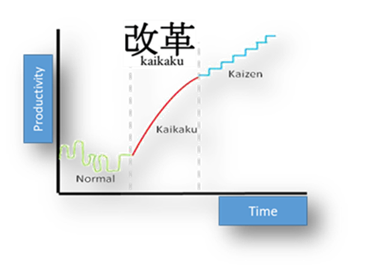

The companies that does not understand the difference between the value chain and the process will suffer on productivity. If they realize a problem in time, they will be able to carry out the transformation gradually - KAIZEN, in a Lean way. If they realize too late, then the transformation will not be carried out by the Lean methodology rather by KAIKAKU methodology for implementing rapid and stressful changes in the short term (Toyota Production System ® Terminology).

4. Micro-management and PUSH method

Micro-management is conducted by companies that do not encourage team approach and do not trust employees. Such companies are recognized by their individual KPIs and by assuming the PUSH method – assigning or dispatching tasks to an individual. Companies that have established trust between management and employees promote the autonomy and independence of the team, and the team takes over the tasks based on the priorities using the PULL method.

The PUSH method can work on a small amount of orders. When the number of orders increases to a few thousand a day, the administration will grow exponentially, and realization will suffer being late. Micro-management companies usually significantly awards management, but not employees, especially those working in the field or shop-floor. Companies that encourage team-based approach the most awards field and shop floor leaders and employees. These leaders are often called Operations Manager or Superintendent or Chief Engineer and in Agile/Scrum terminology they are Product Owners.

Operations Manager (Leaders) works on behalf and in the interest of the owner to meet customer expectations by keeping motivated and satisfied employees.

With the PULL method, you will easily recognize the motivation of the entire team and each team member to complete the work in quantity, time and quality. Thanks to a common goal, each team member looks for the most effective methods to reach the goal while sharing knowledge and innovation with colleagues. Teams are most often multifunctional. The motivation behind this approach comes from rewarding ways. If they accomplish the goal, the whole team gets a reward, and if they don't, nobody wins. The team throws out "intruders" by themselves, those who are not team players. Operations Manager recognizes individuals' talents, promotes them, so that every individual has a chance to thrive. (If you have ever seriously train boxing or karate, you will remember that everyone must did pushups, if only one was messing around in training.)

Simon Sinek: "In the war, officers and soldiers fights for the benefit of many other people, but in the business, many other people (employees) work for the benefit of few (managers and owners)!"

With PUSH, the biggest misconception is that you have better control. These are negative effects of PUSH: (1) the employee will do as much as you give him/her, not as much as he/she can, (2) you will never know someone real abilities or competences, (3) you stifle any flexibility , creativity and innovation, (4) the best employees do not see how they can thrive, so they leave the company.

The PULL method, as seen by Lean, is an integral part of changing corporate business culture, not a process approach. It's an elegant, unobtrusive way to recognize the leaders among you. The leader as well as the top specialist are usually "born". No education will replace the adrenaline if they do what they like. They generate company profits, they will introduce Industry 4.0, AI, IoT, blah… blah into your business. The problem is how to recognize and reward them.

With the PUSH method, nobody succeeded, so neither will you.

Steve Jobs, Apple: "It doesn't make sense to hire smart people and tell them what to do; we hire smart people so they can tell us what to do."

5. EBIT(DA) as the only evidence of progress

Every "traditional" manager knows that EBIT(DA) is the most important measure and top managers has it in their KPI’s. All of them know the methods how to reach targeted EBITDA, even when sales revenues fall. A few of them know when they have exhausted the options and when to look for other job. The Lean method is offered as an alternative to realizing EBITDA by financial methods, that is, when sales revenue falls. Many are too busy to make such changes, and for the others it is too demanding.

We know that the owner sets a goal of at least 10% EBITDA growth every year. We know that EBITDA is generated from 3 sources: Revenue, investments and cost reductions. Any investment in real estate or movable property requires maintenance, and soon or later will generate a new expense.

As much as we invest, if we don’t get it back through cost reductions, productivity gains or increased sales, it returns as a boomerang. If the owner accidentally views EBIT instead of EBITDA, he might recognize that depreciation swallows up the entire margin.

The best companies invest wisely. To invest wisely, you need to have smart people to tell you where to invest based on a value chain to the end customer. These people will recognize waste, find the most optimal solution and effectively bring it into the value chain. In this way, you simultaneously reduce costs, increase productivity and quality in the best possible way.

I'll give you an idea of how to identify these smart people. This method has been applied by a very successful company from the beginning of this article. On an annual evaluation, instead of analyzing KPIs, each employee should bring at least 2-3 improvement initiatives on how to improve the work done by his department / team. If the Operations Manager finds the initiative good, the initiative goes to realization and leader to execute the initiative is employee who propose it. If you continually give bad initiatives or don't give them at all, the company will evaluate that you are not interested, and you will get fired. If you offer good initiatives and are unable to implement them, you remain in the company, but without thrive. If you give good initiatives and able to implement them, career is guaranteed. The Superintendent is very well paid for finding talents as well.

Albert Einstein: "We can't solve our problems with the same thinking we used when we created them."

Conclusion

Lean is not a new methodology. On the contrary, it was created in 1954 in Toyota, Japan, when the country was in deep depression after the lost war. Initially, the primary goal was to establish such a corporate culture that would motivate people to get out from depression and restore their belief in themselves and their abilities. We all know what Japan is today.

Thanks to these Lean values, the companies who promote top leaders and talents (not processes) are applying and adopting new technologies much faster than others. On the other hand, management of the companies that are "TO BUSY" with annual financial goals and EBITDA, do not have time to deal with and lead innovative changes. They expect from processes and process changes to solve all their productivity problems😊.

Any methods, including Lean, if not properly introduced will not produce results. Lean is not a one-time job (project). It is also not a process that you will solve with Change Request. Lean is the continuous introduction and application of all methods of improvement (Genchi Genbutsu - Genba, Poka-Yoke; Muri, Mura, Muda, Hensei, Kanban, Hoshin Kanri, Hyojunka, Jidoka, Taimuri,…). You do not need to know these Japanese words (form) – you need to understand what they propose (content). To be able to do this, a prerequisite is to establish a corporate culture that applies to everyone from management to employees in value chain.

Comments