More about methodologies

Lean Six Sigma

The Lean Six Sigma methodology was created by “merging” a part of Toyota’s manufacturing system (TPS) called “Lean” and Six Sigma. TPS used methods to eliminate process losses (Muri, Mura, Muda), the Six Sigma project implementation method (DMAIC), the statistical method calculated defects and measured process quality ("Defects Per Million Opportunities - DPMO" ). While the Six Sigma method is used in the identification of defects (losses) primarily from collected data (statistics), the Lean method is primarily realies on the experience of consultants in various industries and the “Gemba” method “real place and time”.

The method solves process problems in which:

1. The cause is known and the solution is simple - the so-called. Quick Win

2. The cause is unknown and there are more, and it needs to be discovered and solved - DMAIC

3. Create a new process for a new product (production) - DMADV

4. Establish control over the process flow

LSS DMAIC (Define Measure, Analyze, Improve, Control) describe the stages of implementation of LSS methodology. Each phase has clear results which are the input data for the next phase. The cause of the problem is "searched" using the Value Stream Mapping process design and statistical method for determining the occurrence of defects (Measure, Analyze), and its impact on the final outcome (FMEA - Failure Mode & Effects Analysis). When the cause of the problem is discovered, the design and implementation of the solution (Improve phase) requires consultant experience, frequent approval of top management but sincere cooperation all involved in the problem. The LSS Control phase aims to establish monitoring mechanisms over the process and change to be implemented to ensure the sustainability of the change and to monitor the effects.

Since the LSS methodology, today relies heavily on data from IT systems, in the application of this method there may be additional requirements for change in IT systems (Change Requests).

Toyota / Total Production System TPS - Just In Time

The Toyota Total Production System (TPS) was developed by Sakichi Toyoda, his son Kiichiro Toyoda and engineer Taiichi Ohno in 1954, under the name "Just In Time". The concept was based on Ford’s 1909 to 1922 approach to mass-produced cars (T-Model). It was all long before computers and BPM. The model has been refined over the years and adapted to new technologies, especially Industry 4.0 and 5.0. Toyota is a leader in this field. Soon, many companies in the automotive industry saw that Toyota was producing more pieces, better quality and cheaper, so they took over TPS in whole or in part. Thus, from the principles of TPS, in the west, numerous methodologies of Lean, Agile, Balanced Scorecard emerge ...

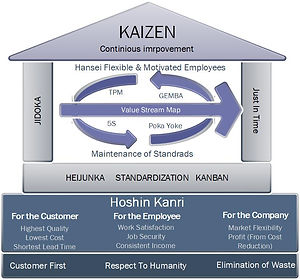

Toyota Total Production System (TPS) is a comprehensive ("Total") approach to all segments of company management, and is based on the philosophy of "Customer first", "Respect for humanity - especially employees" and "Elimination of losses - cost reduction" . TPS views the process as a Value Stream. To automate processes (Industry 4.0,) or to apply Robots or Kobote Industry 5.0, each process step must be maximally standardized and resource optimized (Heijunka). What cannot be standardized or happens unexpectedly is handled by a competent and motivated employee (Poka Yoke, TPM), thus ensuring the best quality and timely response in such cases. TPS calls this approach Jidoka “Automation with Human Touch”. Another great advantage of TPS is the Kanban approach to processes. The TPS Kanban real-time process and information system approach assumes PULL processes, which means that each subsequent process takes as much from the previous one and from the resources (embedded material) as it is able to deliver. It manages these processes using Kanban "pull", "production" and "signal" cards. The Kanban process management model enables self-alignment (automation) of the entire value chain to the end-user and minimum inventory.

Unexpected problems occur in every production or delivery of services, including Toyota's. TPS also offers a solution for such situations - Gemba / Genchi Gembutsu ("Real Location, Real-Time and Real Problem") or TPM (Total Production Maintenance). Gemba says that the problem cannot be solved from the office, but where it arose, and TPM says that it could be solved by the employee who works on the machine, device or tool. However, the initiative to lead the problem is taken by the employee who is directly affected by the problem. For example, an employee who serves a machine or works with a tool should know and repair it in most cases, for which he has all the necessary parts and tools in the workplace. This creates huge maintenance savings, reduces waiting times (production losses), reduces inventory due to downtime, and increases customer satisfaction. These savings are far greater than the cost of higher salaries for the quality and loyalty of motivated employees. Accordingly, the TPS envisages the evaluation of employees on the principles of self-evaluation (Hansei - Self Reflection and 5S) abilities in accordance with the above principles from which the proposal of development of each employee, promotion and reward. Thus, each employee decides on his / her salary and position.

To make the whole system work, Toyota has developed Hoshin-Kanri's dynamic planning and goal-setting tool within TPS. Hoshin Kanri predicts that all of the above has been established. In this way, the business plan is credible, achievable, predictable, and with the help of PDCA (Plan Do Check Act) and controlled in real-time, so it is possible to change it if market circumstances change.

TPS is a comprehensive methodology that operates on all segments of a company's operational efficiency management. It is applicable to all industries, not just manufacturing. Based on our experience in Croatia, the best results have been achieved in the service (especially field service), IT industry (Service Desk, 2.3. Level support), construction industry and manufacturing.

Kyocera Amoeba Management methodologies - "Management by All"

Kyocera Amoeba Management methodology was developed by Kazuo Inamori, owner, and founder of Kyocera Corporation. It has no wide application in the world because the accounting concept is different from the standard accepted in the west. In addition to Kyocera, the methodology is still applied by KDDI (Japan Telecommunications Company), Japan Airlines, Capcom (a software game development company), and some other companies in Japan.

We believe that this methodology will have great potential in the future, especially in business models of acquisitions and outsourcing (separation of individual parts of the company) into separate business entities regardless of ownership. Amoeba Management lays the organizational and accounting foundations of the company on 3 principles: (1) Each internal organizational unit (division, sector or lower) is a "profit center" and has its own "accounting" system, ie it is responsible to operate profitably (amoeba). (2) The second principle is that among the employees, the Leader (manager) is chosen who has the abilities of a leader, and continues to develop in the direction of management. (3) Management by All principle that allows each employee to participate in the management of their department (amoeba). In practice, there are examples that work similarly and very successfully, such as shipping, different production facilities of the same corporation spread around the world. The difference is that Ameba Management goes deeper with application all the way to the department level. It is important that leaders are chosen from existing employees, and they are chosen by employees only, because their salary, future development and advancement depend on the choice of leaders. Each amoeba shares what it has earned.

Amoeba Management transforms a vertical organization (silos) into a network organization (horizontal) where the role of the central management of the corporation is to ensure the most efficient integration of amoebae, support their business and monitor profitability and compliance. The Amoeba Management is primarily intended for industries that can produce different products or deliver services independently of others - they have a closed value chain (one aircraft, one truck, one railway train, one ship or for example a part of a company that only produces refrigerators). Each accounting unit delivers a complete service or a complete product, however each department also produces a complete semi-finished product or delivers a part of the complete service that can also be purchased at the crossroads. In this way, the corporation creates a competitive environment for internal organizational units and motivates them to market behavior and business. The advantage of this approach is the reduction of administrative and IT costs and overhead, because each leader is also an operational employee of an amoeba.

Agile Management

The Agile Management methodology, especially the Agile / Scrum used in the IT software development industry, also emerged from the Toyota Production System methodology. To be agile means to be fast, dynamic, independent, responsible and flexible. Thus in IT one Scrum team develops a specific function in the software that the user can recognize, and so cyclically the entire software. The idea of agile is to split a larger project into smaller functional units that can determine the procedure (sprint or story), duration of production, testing and delivery. Usually the duration of one delivery is 2 weeks. The pre-defined delivery deadline also determines the content that can be "produced" in that period. This standardization achieves predefined delivery dynamics in both production (Heijunka - Load Leveling) and Takt Time delivery. One of the principles of the agile / scrum methodology is that the user does not have to give a detailed specification, but the team should recognize the need, creatively offer a solution that solves the user problem. This approach requires the creativity of an agile team. That is why each team has a technical manager (Scrum Master) and a Product Owner who should understand and convey in an acceptable way the expectations of the users to the team.

The main feature of all the above methodologies is the duration of one phase of delivery, production in the creation of the final product (so-called Takt Time) in the value chain to the user. It is wrong to associate Takt Time with a “norm” because it normalizes activity rather than delivery. TPS uses Heijunka delivery level standardization and load leveling instead of standardization. Therefore, one should be careful in applying these methods as it will not give results if applied incorrectly or selectively.